OUR Partners

In January 2024, the Rieckermann Group announced that they are pursuing a strategic investment in BDI-BioEnergy International (BDI). JR New Horizons, Rieckermann’s strategic investment arm, has secured equal shares in the company alongside EOSS and Kanzler Verfahrenstechnik (KVT), a long-term trusted business partner of Rieckermann. This investment unites the commitment and vision of a circular economy and decarbonization through green production.

With their additional know-how, Rieckermann is now able to provide comprehensive solutions for the conversion of waste to valuable products, e.g. biofuels, to their customers across Asia and the Middle East. BDI´s Biofuels plants can process a remarkable variety of waste oil streams including used cooking oils, animal fats, and other fatty feedstocks from any source.

Leveraging BDI´s expertise, Rieckermann can further provide advanced plastic chemical recycling solutions and retrofits of existing industrial Biofuel plants for increased raw material flexibility and product quality. Customers in the growing market for renewable fuels can be served with innovative processing solutions for hydrotreated vegetable oils (HVO), as well as sustainable aviation fuels (SAF).

OUR TECHNICAL SOLUTIONS FOR CHEMICAL RECYCLING

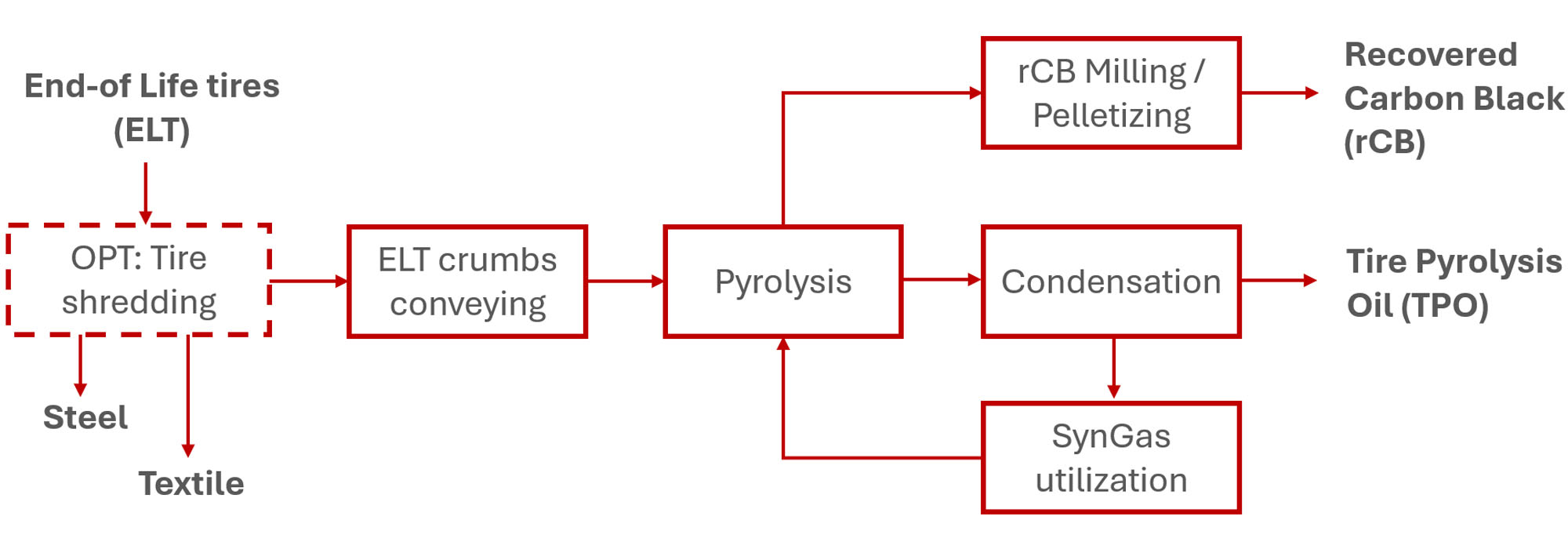

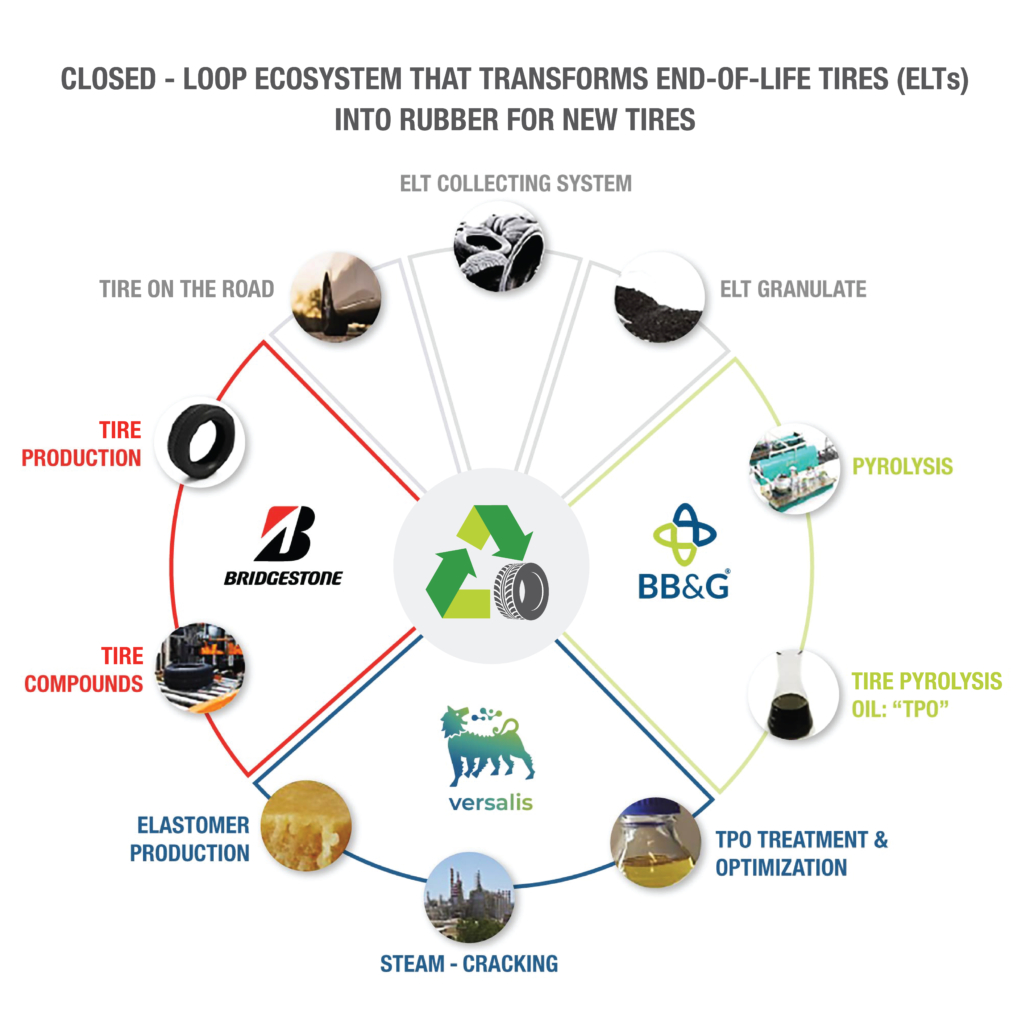

Company BB&G pioneered the tire pyrolysis process in Europe in the last 20 years. Since that time the company has developed into a well-known ELT Pyrolysis technology provider with a commercial plant in operation.

The two main products of this chemical recycling process are tire pyrolysis oil (TPO) and recovered carbon black (rCB).

The permanent focus on the highest quality of TPO and rCB has driven the technology development and made BB&G a unique specialist in this field.

The pyrolysis of BB&G is well established and is on the way to become an important step of the tire life cycle. Both pyrolysis products can be used as substitution of fossil based feedstocks for the production of new tires. This makes tire manufacturing more sustainable. Two worldwide known companies, Bridgestone EMEA and ENI Versalis, are partnering with BB&G in Europe on TPO off-take, this helps to close the circle.

Press release: September 2nd 2024:

Bridgestone > Bridgestone announces the collaboration with ENI Versalis

ENI > ENI Versais confirms the collaboration with Bridgestone

Versalis > Read more about our collaboration

Your advantages with BB&G tire pyrolysis are:

- Fully certified technology and products

- End-of-waste stature for Portugal

- ISCC Plus certification (including GHG emission calculation)

- REACH certification

- High quality products: TPO and rCB (proven by market leaders)

- Best profitability through high TPO and rCB quality

BIOFUELS

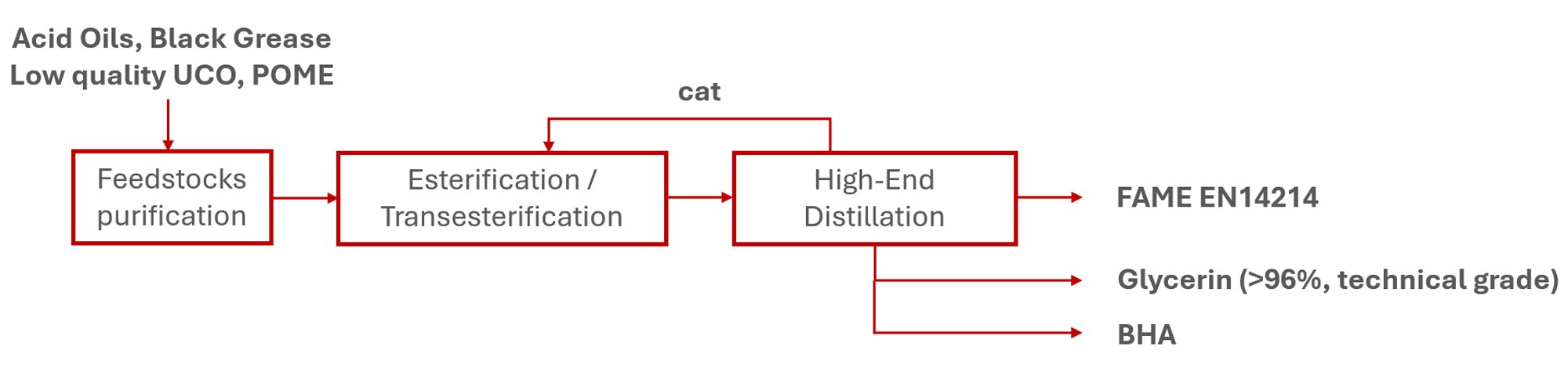

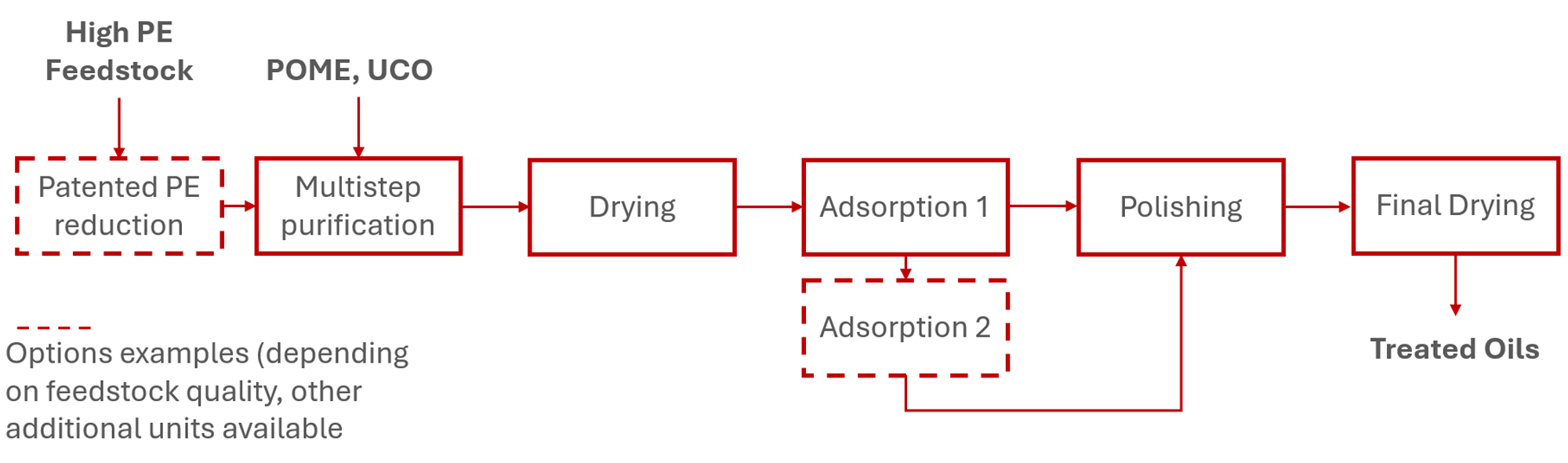

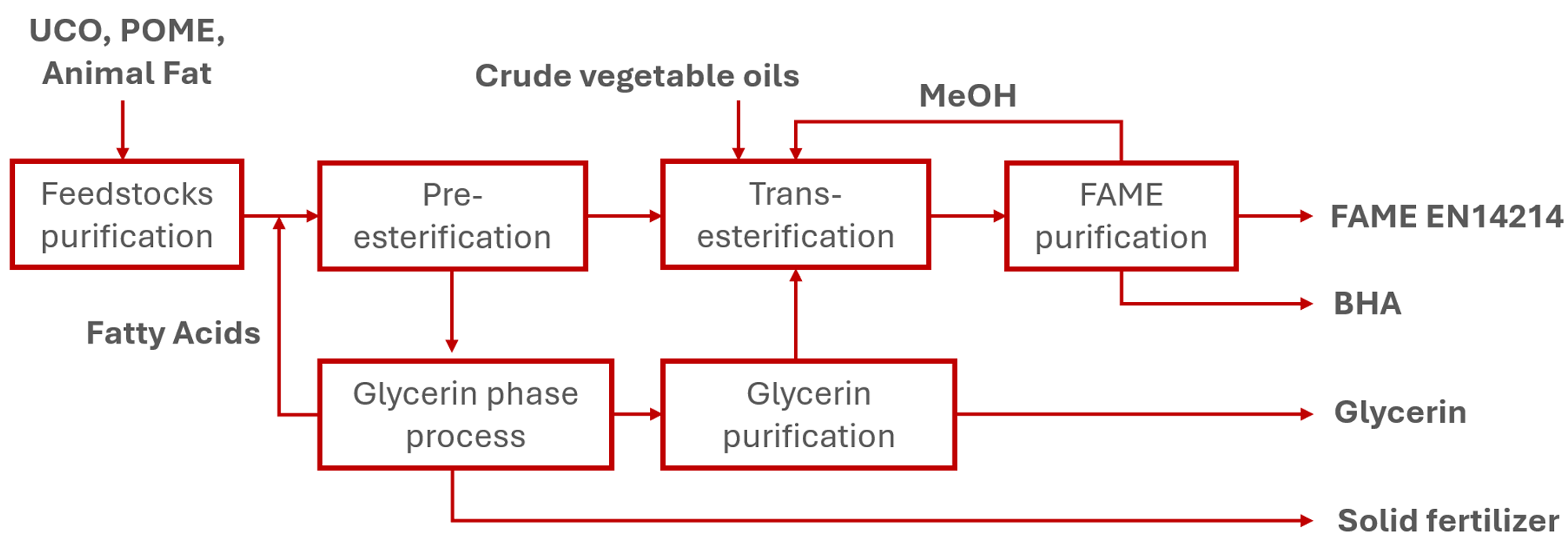

The BDI multi-feedstock process is engineered to convert a wide variety of waste and crude oils, including animal fats, used cooking oil (UCO), palm oil mill effluent (POME), grease trap waste, and all grades of crude palm oil (CPO), into high-quality biodiesel that meets and exceeds the EN 14214 standard.

The multi-feedstock technology can efficiently process feedstocks with free fatty acid (FFA) content of up to 30%; with additional processing units, levels of up to even 70% are also feasible. High conversion yields and superior biodiesel quality are comb¬ined with low operating and maintenance costs, offering a highly economical and sustainable solution for modern biofuel production.

The basic process is illustrated in the graphic below:

Your advantages with BDI’s multi-feedstock technology:

- Highest feedstock flexibility

- Customized design

- 30 years of experience with waste-based feedstocks

- Improved product yield

- Improved OPEX